Tel: (011) 4331.0707 Fax: (011) 4331.5917

E-mail: luftman@phelectronica.com.ar

Offering automatic reporting and real-time alerts for labs and pharmacies, InTemp is an easy-to-learn, easy-to-use temperature monitoring system that dramatically reduces training requirements. Featuring secure data storage and transmission, the 21 CFR Part 11/EU Annex 11 compliant InTemp system includes NIST calibrated loggers with a 1- to 3-year calibration certificate. Presented by Claus Hugo Frykman, Onset's Global Sales Manager of InTemp Shipping & Logistics, and Collin Weingarten, Onset's Senior Manager of InTemp Product Strategy & Support. Webinar topics include: â¢An overview of the InTemp CX400 data logger product line â¢Enhanced automation solutions with the CX5000 Gateway â¢Simplified compliance with the InTempConnect cloud platform & InTemp mobile app â¢Automatic email/text notifications for reporting and critical alerts

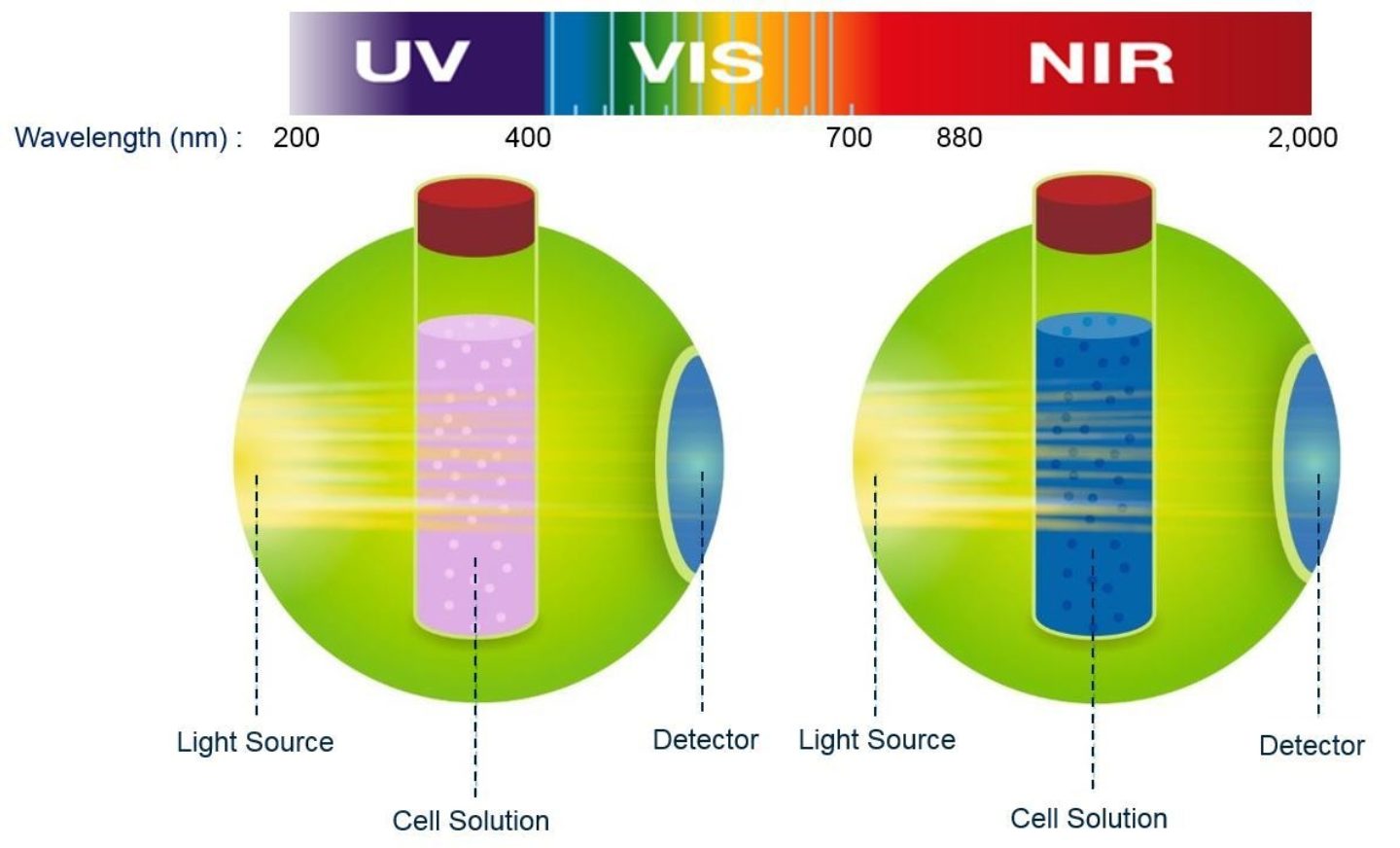

Optical density (OD, sometimes called turbidity) is commonly used to estimate the total biomass or concentration of cells within a suspension. It is important to monitor cell concentrations in fermentation processes to detect and correct process deviations. When measuring OD, light of a specific wavelength passes through a portion of the cell suspension. The components of the cell broth absorb and reflect part of the light from the emission source, and the residual light reaches the detector. The amount of light measured (transmitted) at the detector is directly related to the absorbance of the sample. This method of measuring absorbance is called transmission. Off-line optical density measurements (performed in cuvettes using a visible wavelength of 600 nm = OD600) are affected by the color of the medium, which can absorb some of the visible light and alter the amount of light transmitted to the detector. Offline sampling requires excessive time and energy, and detecting process deviations can take hours, missing critical events.

We'reexcited to announce the launch of our new VisiFerm SURS485-ECS. Discover this versatile new sensor for themeasurement of optical dissolved oxygen in single-useapplications. The VisiFerm SU RS485-ECS combines our provenHamilton measurement technology with upgraded electronics toensure supply security for the future. The sensor offers awide range of connectivity compatibilities. Find out more andlearn how Hamilton's single-use sensor technology can beintegrated into your process, bag, or bioreactor.

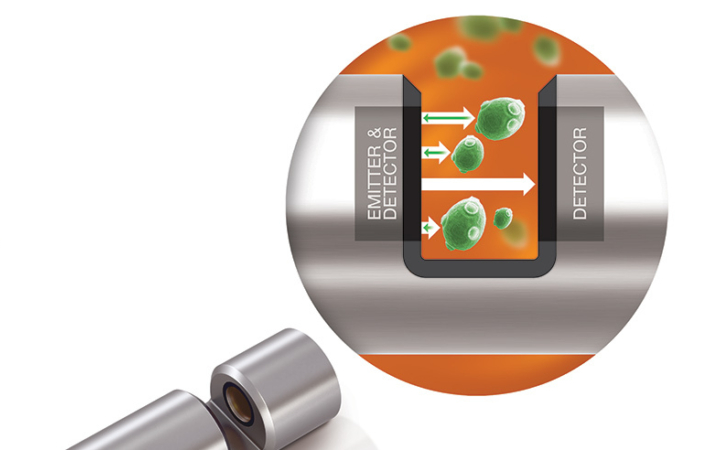

Dencytee Arc features an 860nm LED light source, a rear detector next to the light source, and a front detector in front of the light source. The emitted light passes through a gap of 5 mm before being transmitted to the front detector. Any reflected light is measured at the rear detector. When cells are present in space, they will absorb and scatter light. This results in less light reaching the front detector (transmission) and more light reaching the rear detector (reflection). Unique multi-detector absorbance measurement allows Dencytee Arc to accurately measure total cell density at both low and high cell concentrations. This optical density signal is easily converted to its current offline units using ArcAir software, providing a real-time online total cell density sensor with a wide measurement range.